MIL-HDBK-274A

b. During fueling operations, follow the triangulation grounding procedures outlined in the handbook using temporary grounding rods (see 5.9.2.2).

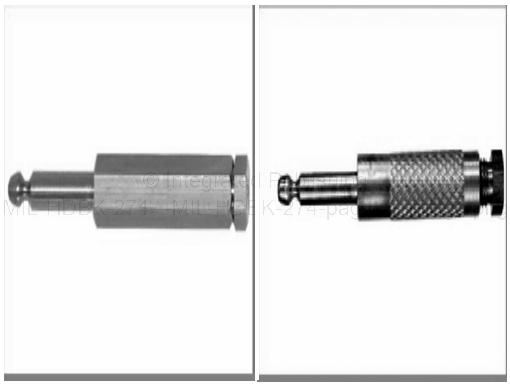

5.10 Grounding hardware/receptacle considerations. In all of the previously mentioned grounding procedures and considerations, the receptacle is the preferred method of connection. Care should be taken to ensure that the receptacle is in good condition. Any evidence that the mating connection is loose indicates that the receptacle is defective and it should be replaced. Periodically, all receptacles should be inspected and their resistance to the aircraft structure should be measured and found to be less than 0.1 ohm. An M83413/4-1 plug, as shown on Figure 18, should be inserted in the receptacle and found to be firmly seated. The pulling force

necessary to withdraw the plug should be between 3.628 and 6.342 kilograms (8 and 14 pounds). A pull of less than 3.628 kilograms (8 pounds) indicates a weak or damaged receptacle; a pull exceeding 6.342 kilograms (14 pounds) may indicate a corroded receptacle. In either case, the receptacle should be replaced. Additionally, the complete cable should be maintained in good electrical condition.

FIGURE 18. M83413/4-1 plug and M83413/4-1 knurled plug.

5.10.1 Use of alligator clips or braided panel strap. The use of alligator clips or braided panel strap to ground or bond aircraft and support equipment is not a safe practice and should be avoided.

5.10.2 Grounding cable. If a grounding receptacle is not available, an approved grounding cable constructed in accordance with MIL-DTL-83413 should be used.

5.11 Aircraft grounding methods. This section provides an overview of the methods for grounding aircraft during aircraft maintenance evolutions including fueling or defueling and loading or downloading of ordnance.

5.11.1 Grounding for shore-based and shipboard operations. The grounding recommendations for both shore-based and shipboard operations are shown in Tables VI and

VII. Painted, corroded, dirty, greasy areas or areas of composite materials should not be used for aircraft grounding points. In addition, if the intended grounding point is loosely connected to the aircraft structure through bearings or springs, an unacceptable intermittent ground could result.

47

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business